Whether we’re seasoned mechanics, dedicated home DIYers, or automotive professionals, grasping the tools we use is essential. One such indispensable tool in monitoring and regulating vacuum pressure is the vacuometer, commonly known as a vacuum gauge. In this comprehensive overview, we explore the inner workings of vacuometers, their diverse applications across industries, and the best practices for their effective use. Additionally, we’ll delve into the advancements in vacuum gauge technology and what these innovations mean for us as users.

Understanding Vacuometers: A Crucial Tool in Various Fields

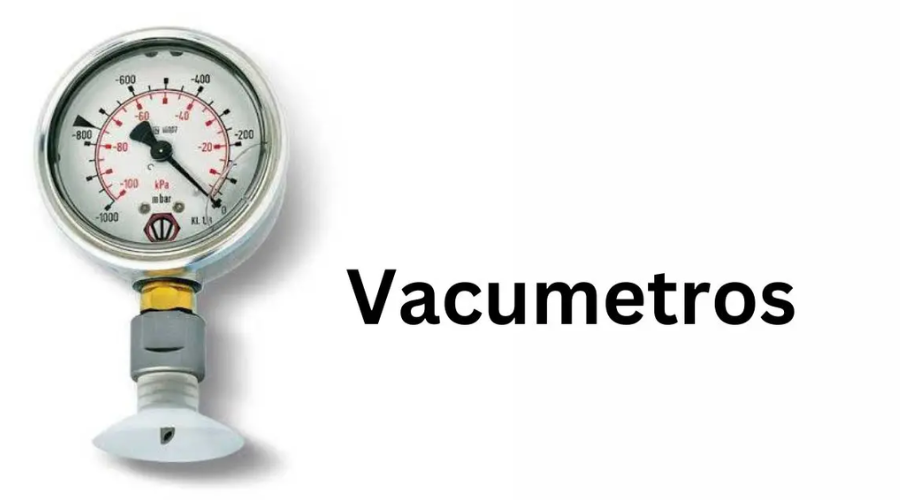

A vacuometer, or vacuum gauge, is a versatile instrument designed to measure pressure levels below atmospheric pressure. With a dial face displaying a needle that moves within a specific range, it indicates the level of vacuum or negative pressure in a system. Typically, these gauges are calibrated in inches of mercury (inHg) or millimeters of mercury (mmHg), making them essential for maintaining efficiency and performance in various systems.

Vacuum refers to the absence of atmospheric pressure, and its measurement is vital in many mechanical applications. From diagnosing engine performance issues to ensuring the smooth operation of HVAC systems and even maintaining home appliances, vacuometers play a pivotal role. Without them, we would rely on less precise methods, leading to inefficiencies and an increased likelihood of incorrect diagnoses.

How Vacuometers Work: The Science Behind the Tool

At the core of a vacuometer lies the ‘bourdon tube,’ a critical component in mechanical gauges. As the vacuum level changes, the pressure difference between the inside of the bourdon tube and the vacuum source causes the tube to contract or expand. This mechanical deformation translates into the rotational movement of the gauge’s needle.

For digital and electronic vacuometers, the process is similar, with pressure changes converted into electrical signals that the device’s processor interprets and displays. The accuracy of vacuum measurement depends on the sensitivity of these pressure-sensing components, ensuring even the slightest pressure changes are captured and presented in a readable format.

Wide-Ranging Applications: From Automotive to Home DIY

Vacuometers find their utility in a broad spectrum of settings:

Automotive

In the automotive industry, vacuometers are invaluable for diagnosing engine issues, particularly those related to the fuel system and exhaust. They assist in adjusting carburetors, setting ignition timing, diagnosing vacuum-operated accessories, and are crucial for performance tuning in both gasoline and diesel engines.

HVAC

For heating, ventilation, and air conditioning (HVAC) systems, vacuometers are essential during system evacuation, where moisture and contaminants are removed under a deep vacuum to prevent future inefficiencies or damage. HVAC professionals also use these tools to test and balance air distribution systems, ensuring optimal performance.

Home DIY Projects

For those of us involved in home DIY projects, vacuometers are handy for tasks like maintaining and repairing appliances, cleaning drains, and testing for leaks in simple vacuum systems such as vacuum cleaners.

Choosing the Right Vacuometer: Key Considerations

When selecting a vacuometer, it’s important to understand our specific needs. Here are some factors to consider:

- Type of Instrument: Analog gauges are typically more affordable and easy to use, requiring no power source. Digital gauges, on the other hand, offer increased precision and often include additional features such as data storage or wireless connectivity.

- Pressure Range: Ensure the gauge’s pressure range matches the measurements needed for your applications. Different gauges are designed for high vacuum, low vacuum, and specific pressure ranges.

- Durability and Use Environment: Consider the conditions in which the gauge will be used. In harsh industrial environments, a rugged gauge with protective features might be necessary.

- Additional Features: Some vacuometers come with advanced features like alarms, peak-hold functions, or compatibility with various fluids and gases, which can be beneficial depending on our needs.

How to Use a Vacuometer Effectively: A Step-by-Step Guide

To make the most out of a vacuometer, follow these steps:

- Prepare the System: Ensure the system is ready for vacuum measurement. This may involve sealing openings and checking for leaks.

- Connect the Gauge: Attach the vacuometer to the system’s pressure port using appropriate tubing or fittings. Verify that all connections are secure and any inline valves are open.

- Take the Reading: Start the system and observe the gauge. Note the stable reading and compare it to the system’s specifications or expected values.

- Interpret the Results: Use the vacuum level to diagnose issues or confirm the proper operation of the system. If the readings are unexpected, further investigation might be necessary to identify the root cause.

Avoiding Common Pitfalls When Using Vacuometers

To ensure accurate measurements and safe operation, avoid these common mistakes:

- Over-Pressurizing the Gauge: Exceeding the gauge’s maximum pressure rating can damage the bourdon tube or cause leaks. Always start at low pressure and gradually increase it while monitoring the gauge.

- Using the Wrong Gauge: Choose a vacuum gauge designed specifically for the type of pressure you’re measuring—be it absolute, differential, or relative pressure.

- Incorrect Attachment: Improper connections can lead to leaks and inaccurate readings. Always use the correct fittings and ensure they are tightly secured.

The Future of Vacuometers: What Lies Ahead

With continuous advancements in sensor technology and digital interfaces, the future of vacuometers is promising. We’re seeing innovations such as the integration of AI and machine learning for predictive maintenance, compact wireless gauges for remote monitoring, and enhanced sensitivity for more precise pressure measurements. Furthermore, the shift towards environmentally friendly practices is spurring the development of vacuum gauges compatible with the latest green technologies and refrigerants.

Conclusion: Harnessing the Power of Vacuometers

In summary, vacuometers offer immense benefits across various fields, providing us with precise insights into system performance and aiding in diagnostics and maintenance. By understanding the science behind these tools and adhering to best practices in their use, we can ensure the efficient and safe operation of our systems.

Whether we’re automotive enthusiasts keen on optimizing engine performance, HVAC technicians working on complex air systems, or homeowners managing routine appliance upkeep, the right vacuometer can make all the difference. Let’s familiarize ourselves with this essential tool, explore its applications, and stay ahead in our respective fields by keeping up with the evolving landscape of vacuum gauge technology.

Uncover the stories behind the stars at BuzzDiscovers.com.